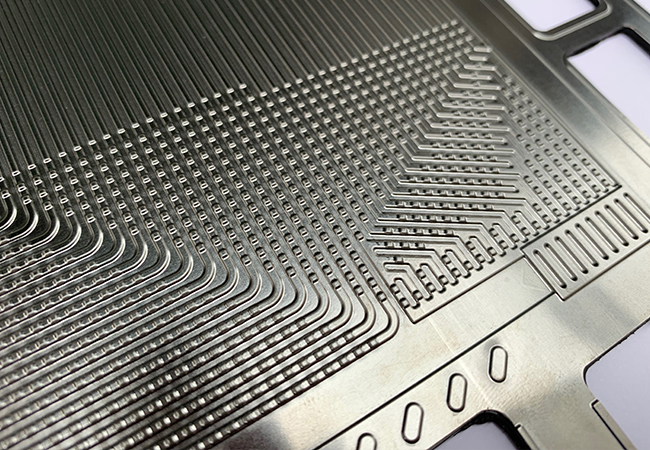

Forming

The separator is the one of core components of a fuel cell stack. Compared to the conventional graphite separator, the metal separator has advantages in lower material and manufacturing cost, higher mechanical strength, and higher power density. It is essential for realizing mass production for fuel cell vehicles. APT has made the utmost use of sophisticated tooling & precise forming characteristics of the servo pressing technique and the hydraulic forming technique to successfully form metal separators with a high aspect ratio. Sheet metal used are mainly stainless steel 316 and titanium.

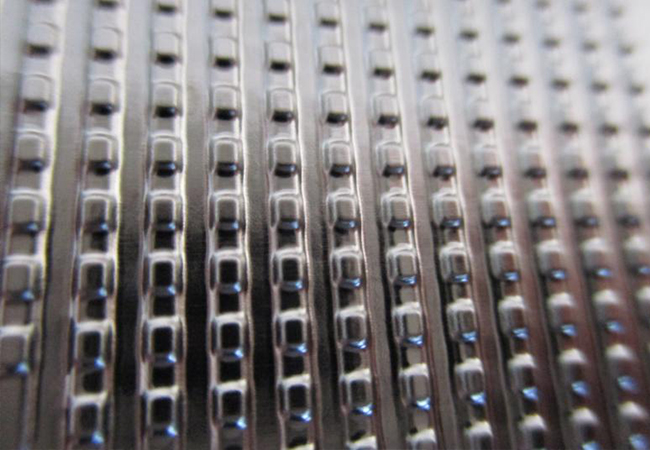

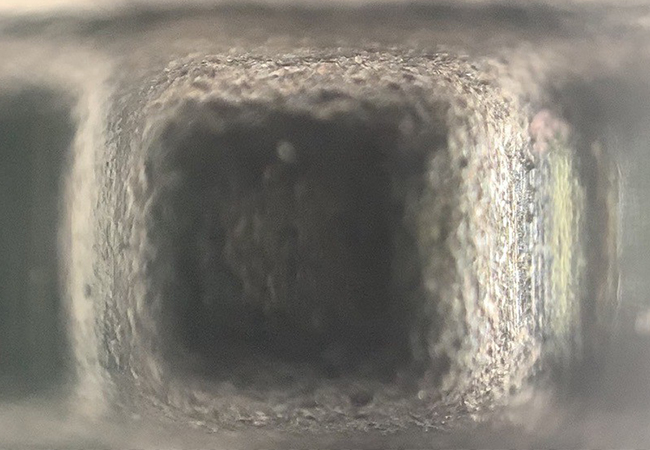

Coating

APT adopts a self-developed nano-level coating, which has excellent electrical conductivity, corrosion resistance, and mechanical properties. The UltraPVD system can significantly increase the plasma ionization rate and plasma density. Under low-temperature conditions, deposit a film with strong bonding force, low internal stress, good conductivity, and strong corrosion resistance on the surface of the substrate, which can significantly improve the output performance and lifetime of the fuel cell. APT has both pre-coating and post-coating technologies, both of which can achieve a mass-production capacity of metal separators.