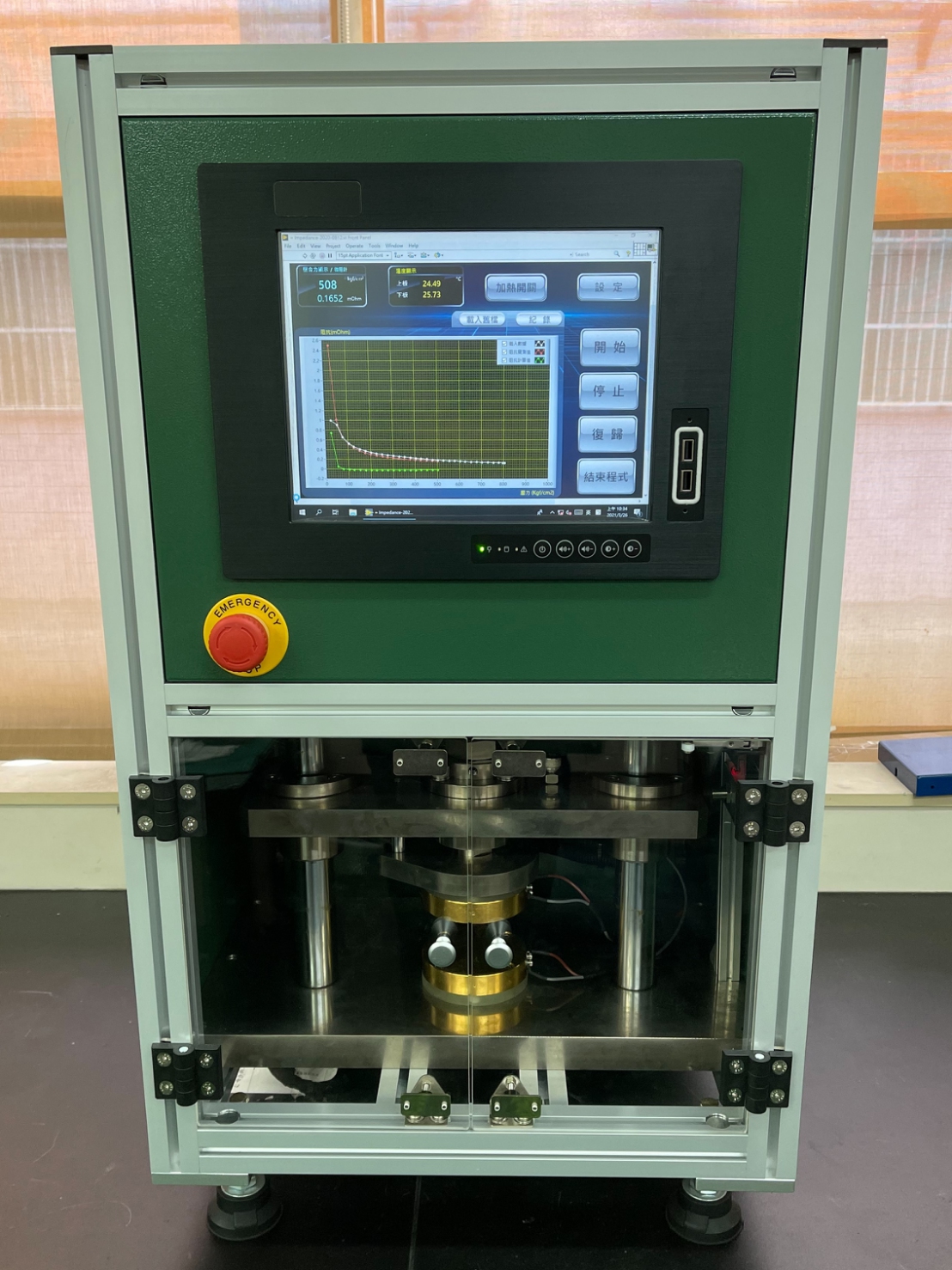

Stacking

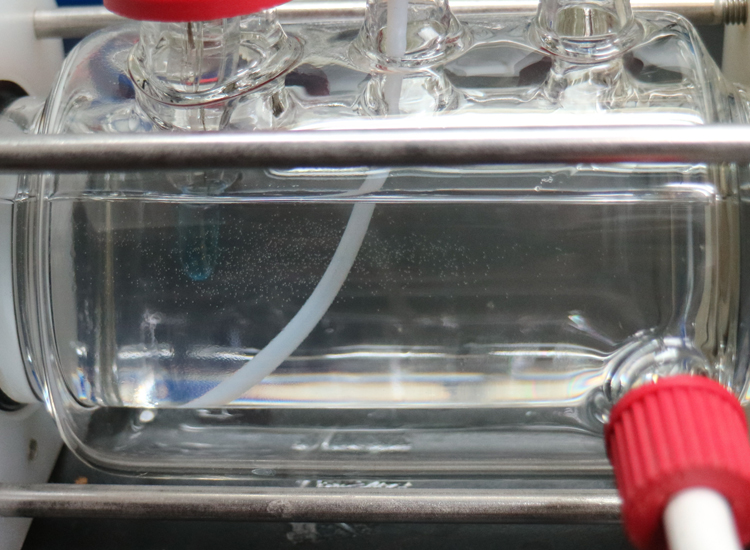

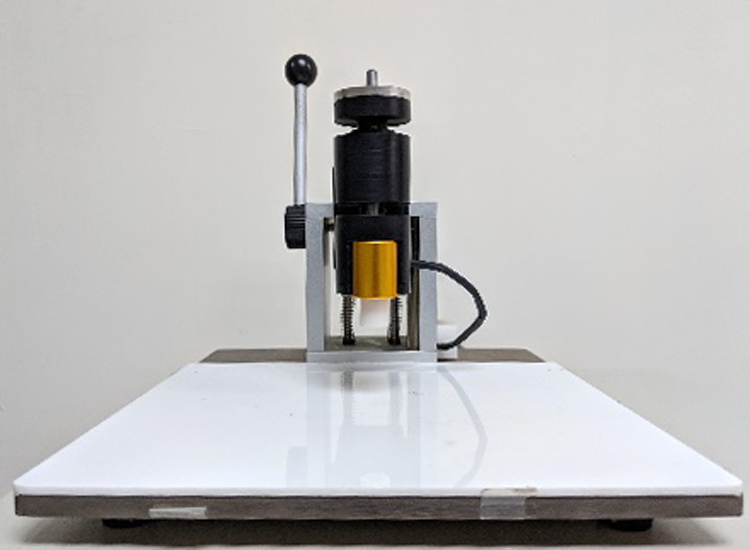

APT launched a horizontal stack assembly machine that keeps the stack assembly in the same orientation as its operation to reduce the gravity effect on the stack performance. With the exclusive fixture and BOSs for Xell®, customers can easily assemble the fuel cell stack according to their requirements. Customers can also design BOSs, fixtures, and housings by themselves to make their specific stacks.